|

|

650 SCFM Heatless Desiccant Air Dryers HL Series by Van Air Systems - HL-650

|

|

MSRP: $19,900.00

Price: $15,920.00

You Save: $3,980.00 (20 %)

Model Number: HL-650

Manufacturer: Van Air Systems

* Whole number only

|

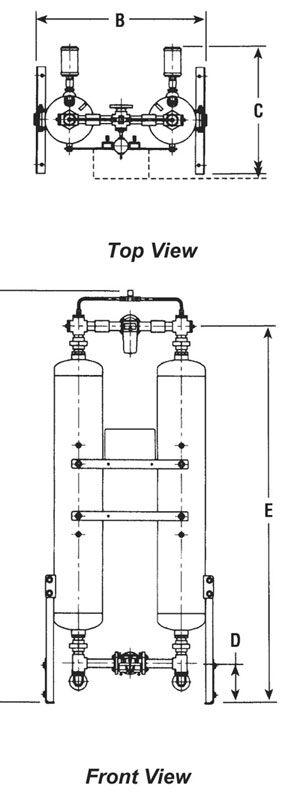

- A : 103

- B : 53

- C : 45

- D : 16

- E : 95

- In/Out Conn.(FLG) : 2

- Desiccant Weight per Tower : 366

HL Series Heatless Desiccant Dryers

Main Features

All Van Air HL Series heatless regenerative dryers 200 scfm and larger include...

HL Series Heatless Desiccant Dryers

Main Features

All Van Air HL Series heatless regenerative dryers 200 scfm and larger include...

- Permanently lubricated Inlet Valve

- Valve Position Indicator

- Purge Metering Valve

- Activated Alumina Desiccant

- Interlock Valve Logic System with Depressurization Safety

- Power on switch/LED

- Control Power Fuse

- Enamel Exterior Finish

- ASME Vessels with:

- Lifting Lugs

- Fill and Drain Ports

- Removable Stainless Steel Desiccant Screens

- Purge Exhaust Mufflers

- Control Air Filter

- Panel Mounted Tower Pressure Gauges

- Panel Mounted Moisture Indicator

- Tower Status LED

- Tower Drying / Regenerating LEDs

- Dual Pilot Valves

- Terminal Strip

- 115/1/60 Supply Power

- Solid State / PLC Control

- NEMA 4 Control Box

- -40F Dew Point

- Switching Failure Monitor LED/Contact

- Cycle Hold Feature

Options

- Full flow safety relief valves

- 220/1/50-60 Supply Power

- Molecular sieve desiccant

- NEMA 7 control box

- Mounted filters & bypass piping

- Pneumatic timer

- Audible alarm

- Digital dew point readout

Controllers for HL Series Dryers

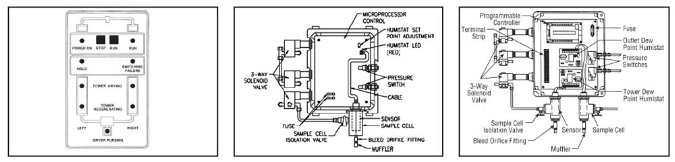

Touchpad Controller

Standard models HL 200 through 2500 Touchpad controller with real-time status display. Includes a Hold Feature which

preserves system pressure and conserves purge air by closing the purge exhaust valve when the compressor unloads or is on standby. The cycle resumes when compressor flow returns.

Cycle Saver™

Standard models HL-3000 and larger Optional on models up to 3000 scfm Includes switching failure monitor LED and contact. Minimizes purge to actual moisture load conditions for maximum savings, lowest operating cost and a -40F dew point.

EMCON II®

Optional on all models

Energy management control adjusts purge to actual moisture load conditions for maximum savings, lowest operating cost and a -40F dew point. Includes features of Cycle Saver, plus high humidity LED, common alarm light and contact and in/out pressure gauges.

- High humidity monitor LED/contact

- Panel-mounted inlet/outlet pressure gauges

Regenerative dryers must have clean, oil-free inlet air!

Lubricated compressors:

Regenerative dryers must have clean, oil-free inlet air!

Lubricated compressors: Dryer must be equipped with proper prefilters as recommended in our filter brochure. An afterfilter should be installed downstream of the dryer to prevent desiccant particle migration

Non-lubricated compressors: A particulate prefilter is recommended to prevent pipe scale and dust from fouling the dryer. If the atmosphere contains condensable hydrocarbons, a coalescing prefilter should also be used. An afterfilter should be installed downstream of the dryer to prevent desiccant particle migration. |

Product Reviews

|

| | |

|

| |

| | |

|

|

|