|

|

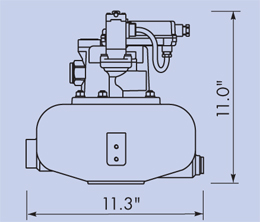

Condensate Drain by Bekomat - 50,000 SCFM - Model 16CO

|

|

MSRP: $2,145.00

Price: $1,501.50

You Save: $643.50 (30 %)

Model Number: 16CO

Manufacturer: Beko Technologies

* Whole number only

|

Bekomat Leading The Way in Condensate Drainage

- Maximum flow rate (scfm) : 5000

- Working pressure (psig) min. : 12

- Working pressure (psig) max. : 232

- Min./max. temperature oF : +34/140

- Connections (inlet) : 2x 3/4" 1 x 1"

- Outlet (hose connector) : 1x 1/2"

- Outlet (hose di) : 1/2"

STANDARD BEKOMAT®

BEKOMAT® 12, 13, 14, 16, 31, AND 32

- Compressor

Around 60 percent of the total condensate is produced in the after cooler of the compressor.

- Receiver

More than 10 percent of the total condensate stems from the air receiver.

- Dryer

Up to 25 percent of the total condensate separates from the vapour in the refrigeration dryer. Therefore, efficient drying requires equally efficient condensate drainage.

- Filter

What is the use of a perfect filter if the condensate drain is not matched to the task or not functioning correctly? Our standard BEKOMAT series of drains are perfectly suitable and have design elements specifically for compressed air filters.

SPECIAL BEKOMAT®

BEKOMAT® 3, 6, 8, AND 9

- Multistage compressor

If the condensate from the intercoolers of a multistage compressor is not reliably removed, it will get into the next compressor stage. The BEKOMAT CV and LA/LP models prevent the impeller of turbo compressors coming under drop attack and eliminates condensate build-up and water hammering. They even manage leaking water-coolers.

- Vacuum

A device specifically developed for vacuum or pres sure less systems with operating pressures from 1.5 to 25 psi (abs.).

- Hazardous areas For application in hazardous areas where spark pre-vention is crucial. The device is rated for use in area II 2G EEx ib IIB T4, i.e., for explosion class II B and temperature class T4. Permissible fluids are: benzine, ethane, methane,

town gas, butadine, ethyl alcohol, methanol, diesel fuel, ethylene, propane, petroleum, heating oil, and hydrogen sulphide.

Bekomat Condensate Drains

Always and Everywhere

Condensate formation is unavoidable. It is always a by-product of compressed air generation and spreads throughout the entire compressed air network. Around two thirds of the condensate is produced in the after cooler. The rest occurs anywhere in the network as the compressed air cools down. This problem is inherent in the system and can cause both damage and higher costs.

The condensate may:

- be aggressive (pH value)

- carry dirt particles (pipe corrosion, pollution of the air)

- contain harmful substances (ambient air)

- be contaminated with oil (oil-lubricated compressors)

It must also be considered that the amount of compressed air condensate produced will vary according to the:

- temperature

- climate zone

- location above sea-level

- relative atmospheric humidity

- distance from the sea

- compressed air flow rate

The solution is a condensate drainage system adapted to the actual amount produced. This will cut costs and prevent damage. BEKOMAT® condensate drains designed for the electronically level controlled discharge of the condensate in compressed air networks functions without unnecessary loss of compressed air and with minimal energy input. Our customers are clearly convinced by the high economic efficiency and reliability of the device: there are now more than 1,000,000 BEKOMAT® units installed worldwide.  |

Product Reviews

|

| | |

|

| |

| | |

|

|

|